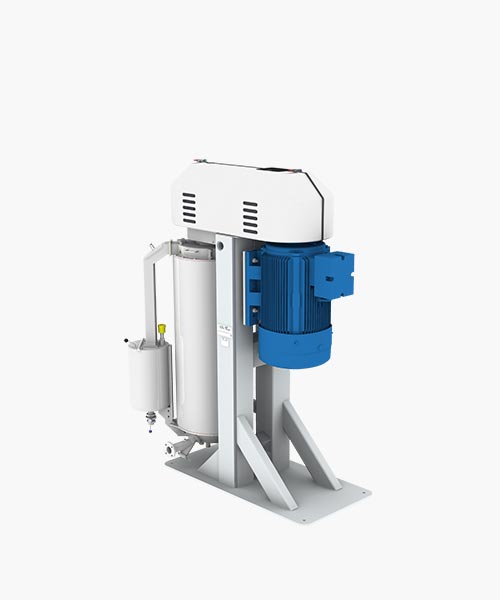

Fine Refining Ball Mill

- Vertical Ball mill system

Wiener original design - High capacities available

- Excellent particle size distribution

- All wear parts are made from the highest grade material

- Well-proven design and world-wide recognized

Specifications / USP's

More information?

Product Information

Description

The principles of grinding are well established: the pre-ground liquor is pumped through the ball mill’s grinding vessel in one or more stages. The refining action is accomplished by a special shaft with agitator arms and diverters rotating in a vertical jacketed grinding tank, which is filled with hardened steel balls. The various layers of grinding elements move in the same direction, but at different speeds. The latest design of the Wiener ball mill exhibits a higher capacity while using less energy. The ball mill is easy to maintain as all wear parts are manufactured from high grade materials and are easily accessible for replacement. The design of the vessel, shaft pin configuration, and ideal parameter control, make this ball mill the most efficient in today’s market.

The vertical ball mill is used for the processing of refined cocoa liquor. This machine is used to further refine the pre-ground cocoa liquor which comes from the beater blade mill or single-stone mill at the initial stage. The vertical ball mill can be used in a 2 – 4 stage refining system, with 1 – 3 ball mills in a sequential row after the pre-grinder.

| Application | Cocoa Liquor Processing, Paste processing |

|---|---|

| Capacities | W-70: 500-1500 kg/hr, W-85: 1500-3000 kg/hr, W-90: 1800-3800 kg/hr |