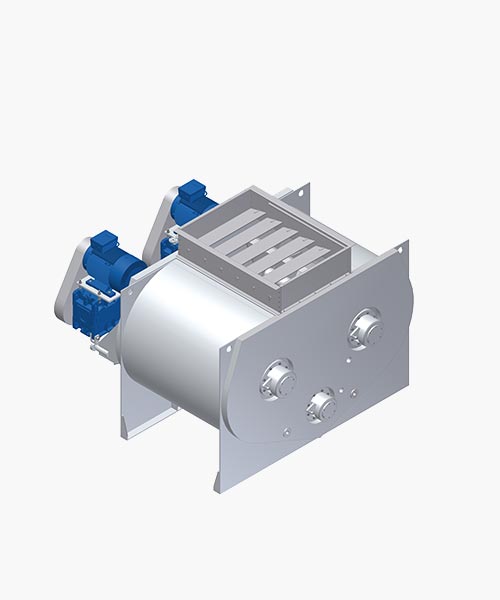

Dry batch conching

- Genuine dry conching with constant high energy input, resulting in lower values for viscosity and yield (with cocoa butter savings possibilities) and reduced conching times

- Rigid jacketed tank designed for heating / cooling purpose, with large louvre design venting hood

- Deflection- and distortion-free single-shaft (RC) or triple-shaft (DRC) execution, each executed with 6 special designed conching elements

- Outside lantern bearing housing with long-life shaft seal

- Easy programmable conching curves for “your” ideal quality and taste

Specifications / USP's

More information?

Product Information

Description

Thouet dry conches are already since 1948 used to improve refined chocolate powder by lowering the natural water content of the chocolate components such as cocoa liquor and, where applicable, milk powder. At the same time the conche removes undesirable flavors that can be found in the cocoa liquor particles. Lowering the water content of the chocolate components improves the rheological values of the conched chocolate. Apart from improving the rheological and flavor aspects, this also achieves a better mixing of the chocolate components during the conching process, leading to a perfect balanced taste of the final product. Cocoa flavor is also transferred to the sugar particles of the chocolate powder during dry conching phase.

The Thouet RC and DRC dry conches work differently to other conches, since they can be filled with refined, dry chocolate powder without adding cocoa butter, fat or lecithin to the conche first!

Genuine dry conching enables a constantly high energy input into the chocolate throughout the entire process, thus resulting in lower values for viscosity and yield compared to differently conched chocolates during the same conching time. Realize that this leads to possible cocoa butter savings of up to 1,0%. Secondly, evaporating of water is much faster in dry product versus pre-wetted (lecithin added) products.

The new RC and DRC series dry conches

The new Thouet RC and DRC series dry conches are executed with more powerful drives and this introduces more energy into the chocolate during conching. The more powerful drives make the total conching time much shorter without the conched chocolate losing any of its quality.

The shorter conching time of the Thouet RC and DRC series dry conches permits the completion of two or three conching cycles every day, thus simultaneously improving the return on investment of the roll-refiners and the conches.

The complete unit is doing its high performance duty full automatically. And it’s progress? This can be checked in a glance via a display, in which you can also save all relevant process data.

| Application | (Chocolate) Confectionary Coatings, (Chocolate) Ice-cream Coatings Processing, Real Chocolate / Couverture Processing |

|---|---|

| Capacities | RC1000: 1000 kg/batch, RC2000: 2000 kg/batch, RC3000: 3000 kg/batch, RC4000: 4000 kg/batch, RC6000: 6000 kg/batch, RC9000: 9000 kg/batch |