GLOBAL MANUFACTURER OF COCOA AND CHOCOLATE PROCESSING EQUIPMENT

Royal Duyvis

Wiener B.V.

EQUIPMENT EXCELLENCE

About Royal Duyvis Wiener

Founded back in 1885 and headquartered in Koog aan de Zaan, the Netherlands, Royal Duyvis Wiener are one of the world’s leading manufacturers within the global cocoa, chocolate and nuts & seeds processing industry. Providing industrial solutions to the biggest companies in the market, Royal Duyvis Wiener supplies state-of-the-art equipment and expertise to facilitate the complete production process from bean to bar, helping their customers to reduce production costs, save energy and minimize downtime for maximum efficiency.

Years in business, established in

1885

Customers with Royal Duyvis Wiener Equipment Worldwide

Machines

to cater your

processing needs

Dedicated staff with full focus on processing equipment

PROCESSING SOLUTIONS FOR GLOBAL INDUSTRIES

Industries Served

FULLY EQUIPPED PILOT PLANT

Technology Center

Customer Testing

Test your recipe innovations on a smaller scale on the state-of the-art equipment in the Technology Center, a unique 2000 m2, full scale pilot plant to support any project from cocoa bean processing to small scale compound and chocolate manufacturing. Walk away with all the data you need and get the expert advice from the Food Technologists.

Research & Development

Following trend & developments in the food & beverage industry ingredients and processing methods change. Want to stay ahead of the curve on what’s happening in the industry and how that affects your processing solutions? We test our machines so you don’t have to. Results are shared via webinars, whitepapers and more. Watch this space for more…

Training & Education

Want to tap into the expert knowledge of the Royal Duyvis Food Technology team? Take a pick from the extensive training program! There is a wide array of training available, ranging from introduction courses for starters in the food & beverage industry to expert sessions and bring-your-own masterclasses. Prefer a bespoke training program? Reach out to discuss the options.

EXCELLENT SERVICE

Repair & maintenance

With decades of experience in the cocoa and chocolate industry we have the knowledge …

Spare

parts

We supply high quality parts for Royal Duyvis Wiener equipment as well as parts for other makes ..

Modifications & revisions

With our very latest technical modifications we can upgrade your existing machinery to …

Inspection & training

Our Service Engineers carry out thorough site inspections. This results in a report, containing …

INNOVATION IS THE KEY DRIVER

What's new?

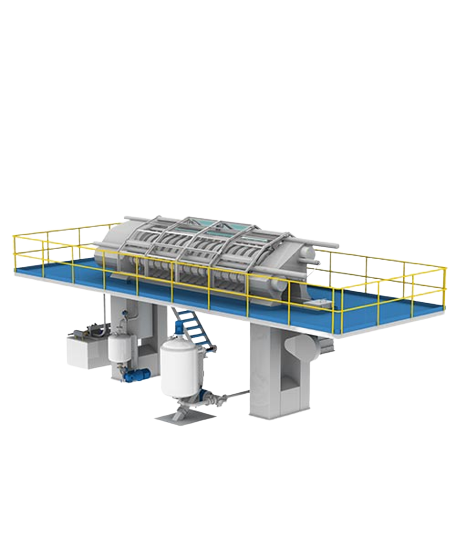

Thouet 5 Roll Refiner

“The 5-Roll Refiner delivers top-notch quality end product, while rolls are interchangeable with all main brand sets.”

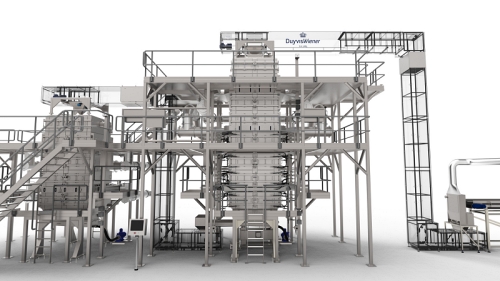

Roaster Showcase

“Showcasing the Batch Nib Roaster, combining best capacity in the business with sustainable choices.”

Log5 Pasteurizer

“Get that all natural, chemical free and food safe 5-log reduction, solution now available for smaller budgets.”

WHAT'S HAPPENING AT ROYAL DUYVIS WIENER?

Latest news & articles

Certifications