Download our free whitepaper

"New chocolate innovations 2022 and beyond"

In a fast-paced global market, it’s difficult to keep up with today’s everchanging consumer tastes and demands and there are many local and global drivers that are influencing these changes. Brands that stay head lead by emulating credibility, being contemporary and innovative.

Types of chocolate

Before diving into the details of the chocolate production equipment, let’s first explore the types/colours of chocolate. There are three main types of chocolate: dark, milk, and white. Dark chocolate contains a higher percentage of cocoa solids, while milk chocolate has added milk powder or condensed milk. White chocolate mass is made with cocoa butter, milk, and sugar but does not contain any cocoa solids. Each type of chocolate requires a specific tempering process to achieve the desired texture and appearance.

Our latests chocolate machinery innovations

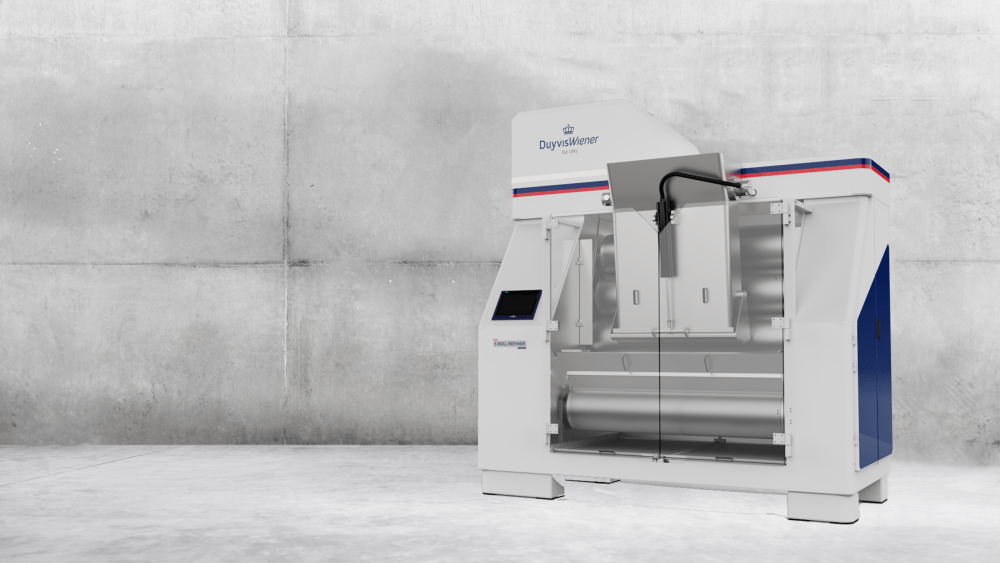

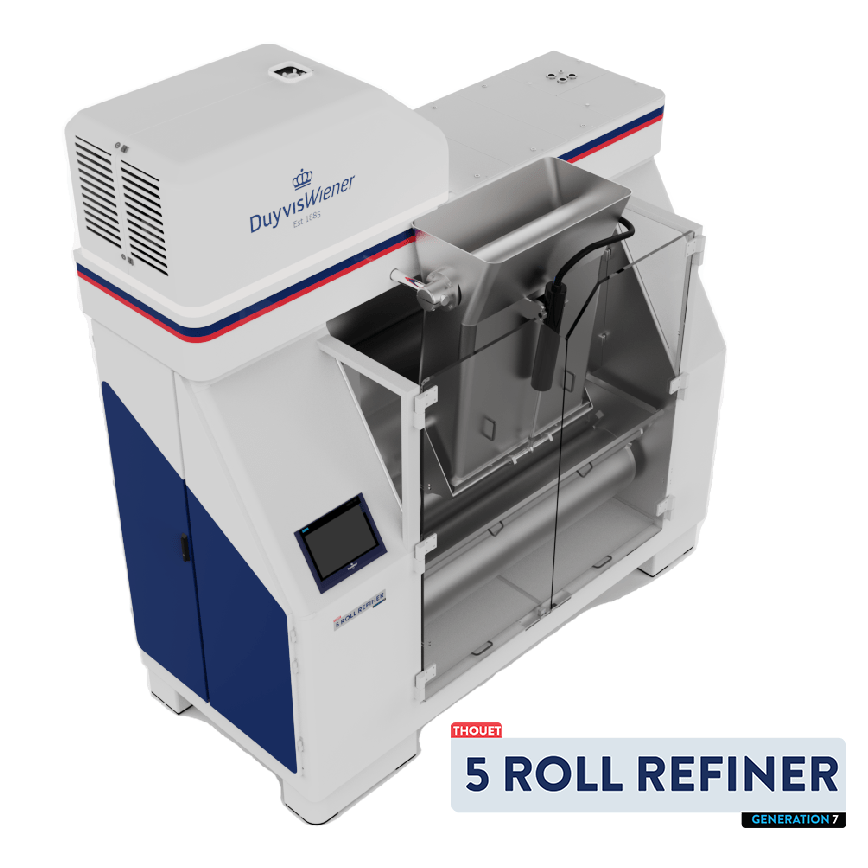

Thouet 5 Roll Refiner

Royal Duyvis Wiener has strong roots in traditional chocolate processing with the Thouet brand. Their passion for the product combined with smart customer-driven engineering solutions made the fundament for the new 5 Roll Refiner, which will be available in January 2023. In addition to delivering on the high product standards you would expect from your

Roaster Showcase

In 2022, we hosted our first Roaster showcase in the factory of Koog aan de Zaan whichallowed us to showcase the Alkalizer, Drum Roaster, and Cooler. An amazing occasion toshare our expertise and innovations with our customers. In addition, customers could learn about the specific benefits of Royal Duyvis Wiener’s Batch Nib Alkalizer, Roaster, and Cooler

How does the tempering process work?

To get informed about the different tempering machines that can be useful for your production line, we first explain the tempering process. The tempering process involves heating and cooling chocolate to specific temperatures to ensure the chocolate has the right crystal structure. When tempered chocolate is melted, the cocoa butter crystals separate and form into different structures, including unstable, beta, and alpha crystals. To achieve the desired texture and appearance, chocolate needs to be cooled and heated to specific temperatures to promote the formation of stable alpha crystals.

The tempering process involves three stages: heating, cooling, and reheating. The heating stage involves melting the untempered chocolate to a temperature between 40-50°C. The cooling stage involves cooling the tempered chocolate to a temperature between 26-28°C while stirring the chocolate continuously. This process promotes the formation of stable alpha crystals. The reheating stage involves heating the chocolate to a temperature between 30-32°C to remove any unstable crystalline structure and ensure the chocolate is smooth and glossy. Now we know more about the hot chocolate melter and tempering of chocolate, we move on to the different machines that are available on the market.

Which different tempering machines are on the market?

Tempering chocolate by hand can be a time-consuming and challenging task. As a result, tempering machines were invented to make the process more efficient and consistent. There are various types of tempering machines available on the market, including:

- Traditional chocolate tempering machine: This type of machine uses a column design and a heating and cooling system to temper chocolate. The chocolate is poured into the top of the machine and flows through the column, where it is heated and cooled to achieve the desired texture and appearance.

- Automatic chocolate tempering equipment: These machines are computer-controlled and use advanced technology to temper chocolate. They offer precise temperature control and can temper large amounts of chocolate quickly and efficiently.

- Batch chocolate tempering machine: This type of machine is ideal for small to medium-size chocolate production. It uses a bowl size up to 30-40 kgs of chocolate per hour to heat and cool chocolate.

- Continuous tempering machine: This type of machine is ideal for large-scale chocolate production. It uses a continuous table for chocolate blocks metering and can produce up to 2000 kgs of bulk chocolate per hour.

Explore our newest 5 Roll Refiner

“The smart design of this machine allows universal roll management. Do you have main brand rolls and gears in your warehouse? Not to worry, all main brand rolls and gears can be fitted into this machine with the service you’re used to from Royal Duyvis Wiener technical support engineers”

What are the features and functions of tempering machines?

Tempering machines come with various features and functions that make them ideal for chocolate production. At Royal Duyvis Wiener, we can inform you about the right specifications for your specific tempering machine. Some of the features and functions that could be include are:

- Automatic starting timer: This feature allows the machine to start automatically at a predetermined time, making it convenient for chocolate production.

- Digital temperature control system: This feature allows precise temperature control and ensures consistent quality chocolate products.

- Flow-stopping pedal: A flow-stopping pedal allows the operator to control the flow of chocolate into moulds, ensuring accurate dosing and reducing waste.

- Extractable auger: This feature allows easy cleaning and maintenance of the chocolate equipment.

- Auger pump with speed controller: This allows for adjustable chocolate flow, making it easier to control the amount of chocolate being tempered.

- Programmable foot pedal: This feature allows the operator to control the chocolate fluidity using their feet, leaving their hands free for other tasks.

- Back-order moulding accessory: With this feature the machine could be used for moulding chocolates, adding versatility to the machine.

- Automatic dosing: This feature allows for accurate dosing of chocolate into moulds, ensuring consistent product quality.

- Removable auger: This feature allows for easy cleaning and maintenance of the machine.

- Compact size: Some tempering machines are designed to be compact, making them ideal for when you have small chocolate production facilities.

Chocolate Tempering Machinery

The benefits of using tempering machines

Using a tempering machine offers various benefits for your chocolate production, including:

- Consistent temperature: Tempering machines provide precise temperature control, ensuring consistent quality chocolate products.

- Energy savings: Some tempering machines use special Energy tempering technology, which reduces energy consumption by up to 80%.

- Reduced chocolate waste: Precise dosing and flow control reduce chocolate waste, leading to cost savings.

- Increased production efficiency: Tempering machines can temper large amounts of chocolate quickly and efficiently, increasing production efficiency.

- Improved chocolate quality: Precise temperature control and crystal structure formation result in high-quality chocolate products with a smooth and glossy finish.

Conclusion

Tempering machines are essential tools in chocolate production, offering precise temperature control, reduced chocolate waste, increased production efficiency, and improved chocolate quality. There are various types of tempering machines available, each with its features and functions, making it easy to find one that fits your specific needs. By using a tempering machine, you as chocolate makers can produce consistent, high-quality products that will satisfy chocolate lovers around the world.

Related posts

Cocoa bean: Butter production, applications & benefits

Discover the advantages and applications of cocoa butter. This butter is a versatile and popular ingredient in both the food and beauty industries. This pale yellow vegetable fat extracted from cocoa beans is renowned for its unique aroma reminiscent of chocolate and its smooth texture. Cocoa butter is an important component in chocolate-making, and it

Why ball mill grinding is important for delicious chocolate

Learn about ball mill grinding and how it is used in the chocolate production industry. Discover the advantages and components of ball mills, and get to know more about the different types, materials, and processes involved. Ball mill grinding process Ball mill grinding is a critical process in the chocolate production industry. It involves crushing

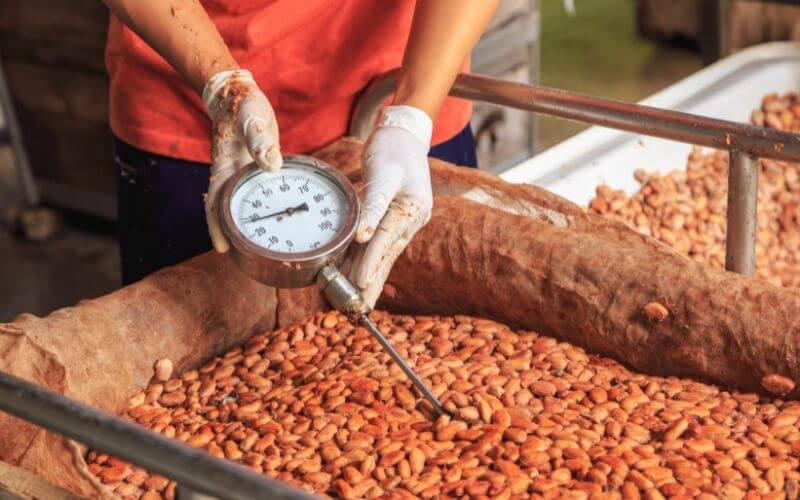

Understanding the cocoa bean fermentation process

Did you know that the quality and flavor of chocolate depend on the fermentation process of cocoa beans? The cocoa bean fermentation step is crucial in the chocolate production process, and it affects the taste, texture, and aroma of chocolate. In this article, we will explore the microbiology of cocoa fermentation, the role of acetic

Everything you need to know about the cocoa nibs grinder

Chocolate is an indulgent treat that has been enjoyed by many for centuries. Whether you are a chocolate manufacturer or a craft chocolate entrepreneur, you understand the importance of the cocoa nibs grinder in the chocolate making process. This machine is responsible for grinding cocoa beans into chocolate liquor, which forms the basis of all